| |

| |

| |

|

|

The beginning of FreesTech's product line began back in 1967 when its two founders designed a tabletop conveyor system for the Food and Dairy Industry utilizing the then newly introduced 880 Series tabletop chain. Conveyors were manufactured and shipped from a renovated barn in the farm country of Lancaster County, Pennsylvania.

|

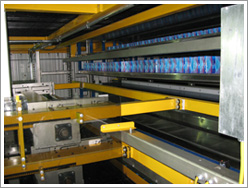

The founders designed and introduced the first TRI-Tray system for freezing turkeys in 1971 which is still being used today. Now in its seventh design series, nearly four decades later, the system is used for cold temperature processing food products ranging from sour cream to frozen meats at rates as high as 50,000 lbs/hr. TRI-Tray’s highly automated operation provides a profitable business solution for Food and Dairy plant facilities. |

|

Through out the past three decades FreesTech has identified and provided new business solutions in these processing plant areas to many successful clients. These areas are shown below:

Bulk Receiving Bulk liquid ingredient receiving

Kleen-Line Conveyor In plant sanitary conveying systems

TRI-Tray System Cold temperature processing for packaged and cased items

TRI-Stacker System Automated storage and retrieval (AS/RS) of pallet loads

SORS System Storage, order selection and replenishment, a true solution to order selection of less than full pallet loads

and newly introduced

Auto-Pal Automated pallet loading for multiple lines |

|

|

Parkland Services, Inc. Ph: 717-560-7560 Fax: 717-560-7587

© Copyright Parkland Services, Inc 2009. ALL RIGHTS RESERVED.

|

|