| |

|

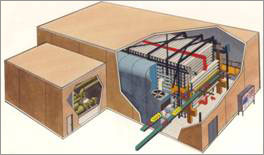

TRI-Tray Series 7000

The World¡¯s First truly ¡°Green¡± Cooler, Hardener and Freezer

Six Reasons TRI-Tray is the Best Business Choice |

1. Rapidly cools or freezes packages and cases of Food and Dairy products at feed rates up to 50,000 Lbs/Hr. |

|

|

2. TRI-Tray utilizes the patented Fusion Cell process freezes your product faster while reducing energy costs by as much as 60% less than competitive systems. Increases your business profits and cash flow by reducing inventory. |

3. Isolated Fan Coil system assures the best air distribution over the product to afford the best quality for the food product. Reduces frost formation and eliminates costly defrost cycles during production. Available with Fan Coil installations beside or above the TRI-Tray. |

|

|

4. Lowest maintenance costs of all conventional air blast coolers and freezers. 5.0 year lubrication cycles for most operations. All gear reducer drives are direct drive eliminating chains and sprockets. Electrical motors are driven with Variable Frequency Drives (VFD). |

5. FreesTech can supply the TRI-Tray as a ¡°turn-key¡± project including engineering, installation, enclosure panels, electrical panels, lighting, feed and discharge conveyors and the mechanical refrigeration package. Eliminates costly subcontractor errors and maintains your project budget. |

|

|

6. TRI-Tray¡¯s capability of handling a wide variety of package and case sizes means there is a good chance you will see a return on your investment when your plant has to change sizes to meet future customer demands. Unlike plate freezers and most spiral designs, TRI-Tray can be designed to adapt to most changes your future customers may demand. It is one of the reasons many TRI-Trays are still in operation after nearly four decades of service. |

For more reasons why the TRI-Tray is the best Business Decision for your Company contact info@freestech.com

Or Phone

Main Office: 717-560-7560

Midwest office: 816-407-9749 |